Advanced materials manufacture - Ultima Forma

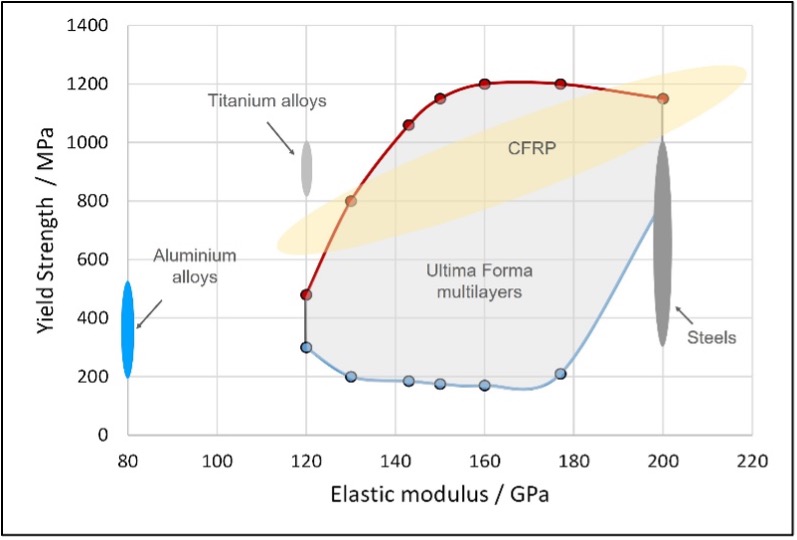

Ultima Forma's technology builds on Prof Bushby’s research at Queen Mary Univeristy of London's School of Engineering and Materials Science that showed why materials are stronger when some feature of their structure is restricted to micrometre length-scale, ‘smaller is stronger’. Ultima Forma combines materials science with advanced manufacturing techniques to provide new solutions for engineering challenges in the transition to a zero carbon future. Ultima Forma has turned this research knowledge into a scalable manufacturing process that creates multifunctional components. The company uses a unique electrodeposition process to produce light-weight, high performance, metal components. The process uses earth-abundant elements, low energy, and almost zero waste as metal is deposited atom by atom. The process is a low cost, additive, net-shape forming process, that allows a different approach to engineering design, particularly for hybrid material systems, making them faster from design to manufacture, lighter-weight & stronger. The technology is finding applications in the most demanding engineering situations. For example, light-weighting in aerospace structures, functional components in satellites and new liquid hydrogen fuel systems for zero carbon aviation.

Multilayer manufacture opens new material design

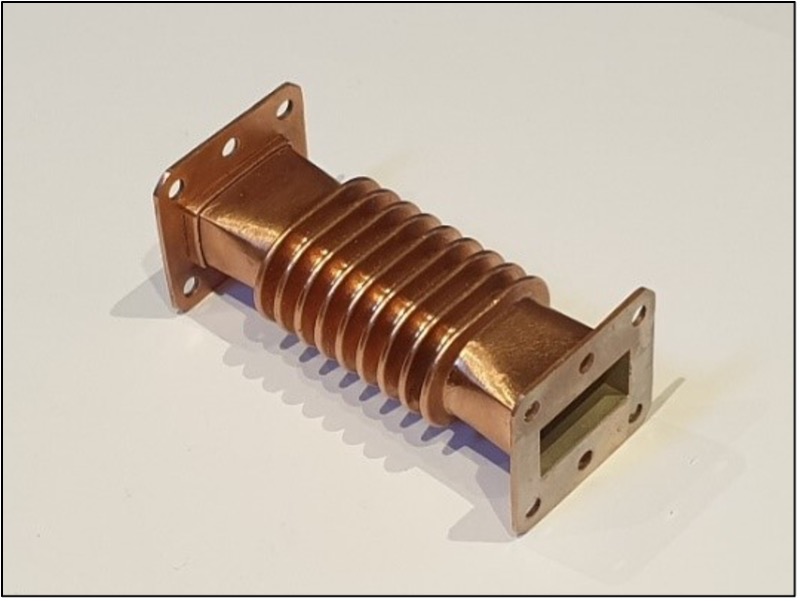

Flexible satellite waveguide

- More information: Centre for Sustainable Engineering and Ultima Forma

- Contact: Prof. Andy Bushby