Tyre Design to Reduce Environmental Impact

At Queen Mary University of London, we have been researching elastomer behaviour with many of the world’s leading rubber companies for more than 60 years.

A recent area of focus has been to understand the mechanisms which govern the abrasion behaviour for different types of tyres. Under normal driving conditions, tyres generate two different types of wear debris. The first is a mechanical abrasive wear process where solid rubber particles are generated and the second is a chemical activated “smear wear” process, where a sticky low molecular weight debris is generated. Both materials are eventually deposited onto the road surface and into the environment.

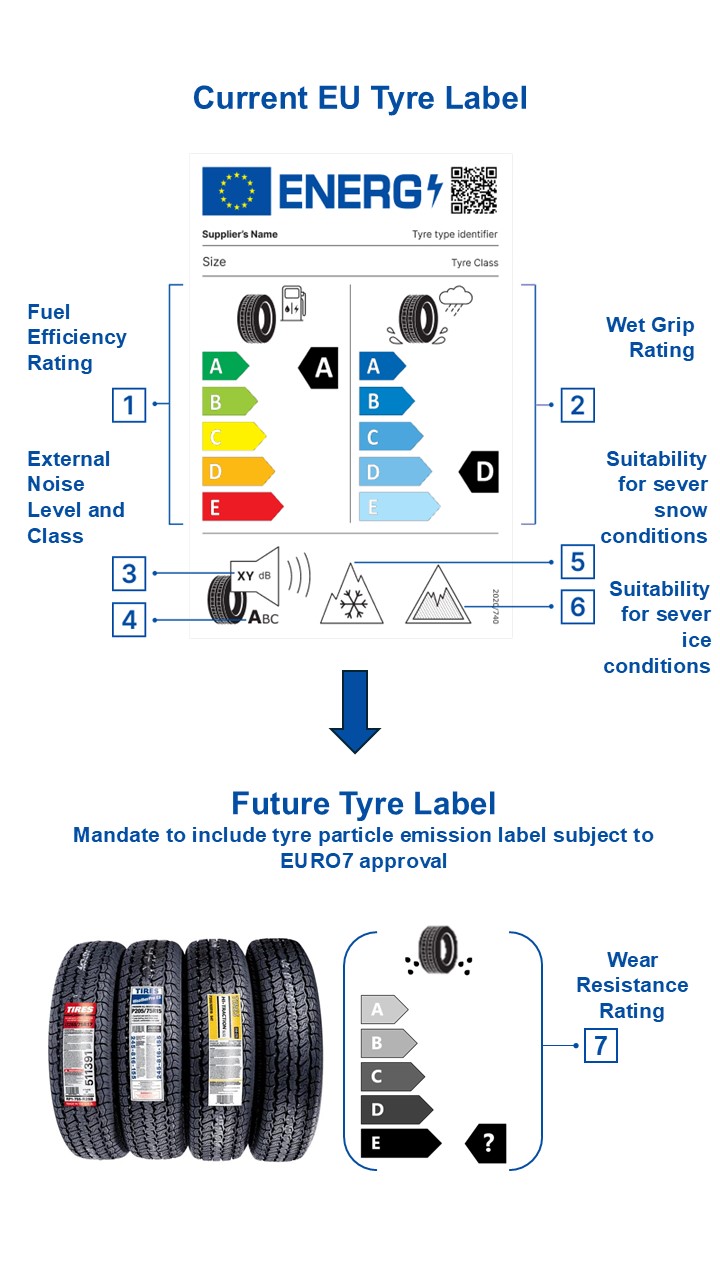

Our facilities at Queen Mary include a wide range of lab-based abrasion test machines. These systems can replicate the cyclical loading behaviour encountered at the tyre-road interface. They can evaluate and compare the effect of the two wear mechanisms for different tread compounds under different driving conditions. Then, through different characterisation equipment we can understand the properties of these particles and how they would behave in the environment. Imminent legislation will require all tyres to be more abrasion resistant and so we are at the forefront of working out how to achieve that. If you want to know more about our work on friction and abrasion of elastomers then contact j.busfield@qmul.ac.uk.

Tyre Wear Classification

More information: Centre for Intelligent Transport

Contact: Prof James Busfield