Ultima Forma Manufacturing

Ultima Forma https://www.ultima-forma.com/ was founded by Professor Andy Bushby in SEMS. Building on pioneering research in the micro-mechanics of materials, the company has developed and commercialised a novel manufacturing process that can create complex multi-functional components with locally-tailored nano-engineered properties.

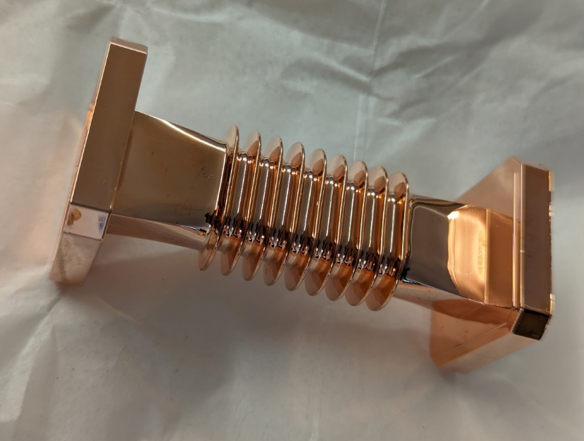

They can build light-weight metallic components to metre scale structures using their patented process. This can produce functionally graded material properties, by depositing nano-scale multilayers to control the material properties across a part and through the wall thickness allowing the properties to be optimised.

These variable properties range across structural, thermal, electrical and RF in order to build efficient multi-functional parts that will save the users weight, assembly time, cost, and simplify their supply chain. Ultima Forma’s expertise in electroforming chemistry allows them to design, engineer and manufacture parts that were previously thought impossible.

Awarded the prestigious ‘Shaping the Future Award’ in 2023 by the Aerospace Technology Institute, Ultima Forma are developing new technologies for the hydrogen economy, in energy and advanced transport solutions; in space technology for high throughput data transfer in 5G communication networks; and advanced manufacturing processes, using their Ultim8 design tool to find new, sustainable and resilient design solutions for the UK’s leading industrial companies.

Multifunctional component for space applications. Materials are tuned from spring properties in the central flexible bellows to tough, ductile materials in the end plates in a single component that weighs only 13.5 grams